University of Colorado Boulder’s Charles Wade develops OpenVCAD, a Python-based tool that lets engineers design complex multi-material 3D objects with code-driven precision, making advanced 3D printing accessible to all.

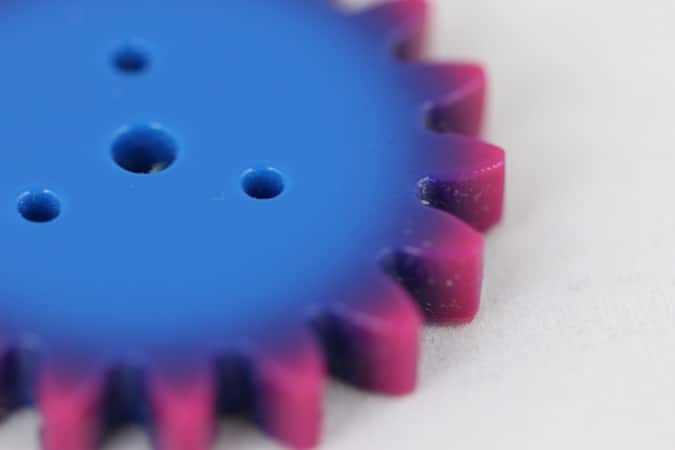

A new open source software tool, OpenVCAD, developed at the University of Colorado Boulder, is transforming the way engineers create gradient, multi-material 3D-printed objects. The Python-based tool allows users to import the repository and start designing with a single line of code, democratizing access to advanced 3D design without licensing barriers.

Charles Wade, a PhD student in computer science, said, “This is the first multi-material, code-based design tool that is widely available. Unlike traditional CAD software, where you’re forced to sketch everything out for each change and you cannot represent graded materials, our tool allows users to change one small variable and watch the whole design update in an easy way.”

Developed in the Matter Assembly Computation Lab led by Assistant Professor Robert MacCurdy, OpenVCAD addresses the limitations of conventional CAD tools, which typically define only an object’s outer boundaries and assume a single material inside. MacCurdy explained, “There’s certainly a history of multi-material design study and practice that existed well before OpenVCAD. But we believe the overhead of writing specific code for specific projects every single time prevents engineers from doing as much design as they could.”

OpenVCAD allows code-driven mapping of both shape and material distribution, supports seamless multi-material gradients, and has been demonstrated on printers capable of using up to five materials simultaneously. Applications span medical modelling, robotics, and structural engineering, enabling surgeons, roboticists, and engineers to design highly customised parts with unique mechanical properties.

MacCurdy added, “We’re able to rely on OpenVCAD’s core capabilities to represent multi-material objects in a bunch of different domains. We’re really hoping this approach to multi-material design takes off.”

Findings have been published in Additive Manufacturing, and the team aims to build a growing community of external researchers to make advanced multi-material design widely accessible and reproducible.