Designed to overcome the challenges of modern industrial workloads, this innovative platform combines the reliability of RHEL with open-source flexibility, enabling seamless AI, data aggregation, and more—right at the industrial edge.

Red Hat Enterprise Linux (RHEL) has been a backbone of data centers and cloud solutions for three decades, supporting critical systems from websites to enterprise applications. Building on this legacy, Red Hat is now expanding into industrial applications, leveraging its Device Edge platform to bring open-source reliability and performance to the industrial edge.

Industrial environments face unique challenges, including limited integration with modern IT and difficulties in adopting new technologies seamlessly. Traditional systems struggle to accommodate new workloads such as AI, data aggregation, and computer vision, which impedes modernization. The Device Edge addresses this by offering an open-source, resilient operating system tailored for these specific needs. By bridging IT and Operational Technology (OT), it simplifies management and reduces the need for on-site IT expertise, cutting costs and time, especially in remote locations like factories and oil rigs.

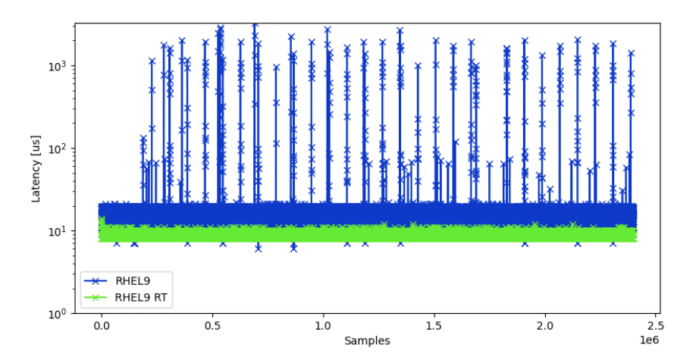

One standout collaboration is with German Edge Cloud, where the company’s OpenShift powers the ONCITE Digital Production System, providing real-time monitoring and data management in manufacturing. This partnership exemplifies how the Device Edge can support advanced industrial functionalities on the shop floor. The Device Edge has continued to evolve, recently demonstrating capabilities for deterministic performance essential for industrial control, thanks to innovations like Intel’s Cache Allocation Technology (CAT) and Time-Coordinated Computing (TCC). These improvements enable seamless, consistent performance, vital for applications demanding low latency and reliability.

The company’s lightweight Kubernetes variant, Microshift, enables container orchestration on edge devices, supporting digital solutions like ABB Ability Edgenius. To ease deployment further, it introduced Image Mode for RHEL, allowing industries to use a single image across multiple platforms, from virtual machines to bare-metal industrial PCs. The Device Edge for Industrial Control, now in developer preview, is tuned for high-demand, deterministic workloads. This build promises simpler deployment for critical applications, bringing advanced open-source capabilities to industrial environments and reinforcing the industrial sector’s shift towards Linux and open standards.